An 18-month federally-sponsored project led by the Georgia Institute of Technology will develop much-needed curriculum to train workers for the fledgling cell manufacturing industry.

Research teams at the University of Georgia (UGA) and the University of Pennsylvania (UPenn), along with four private firms, are also taking part in the $1.4 million effort to develop training materials for cell and gene therapy manufacturing and cell-based biologics manufacturing.

“Cell-based therapies have the potential to benefit many patients, but to achieve that we need a highly-skilled workforce to support the growth of the cell manufacturing industry,” said Chuck Zhang, the principal investigator of this project and Harold E. Smalley Professor in the Stewart School of Industrial and Systems Engineering at Georgia Tech.

The curriculum development project is part of the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL), which the U.S. Department of Commerce is supporting with a five-year, $70 million grant.

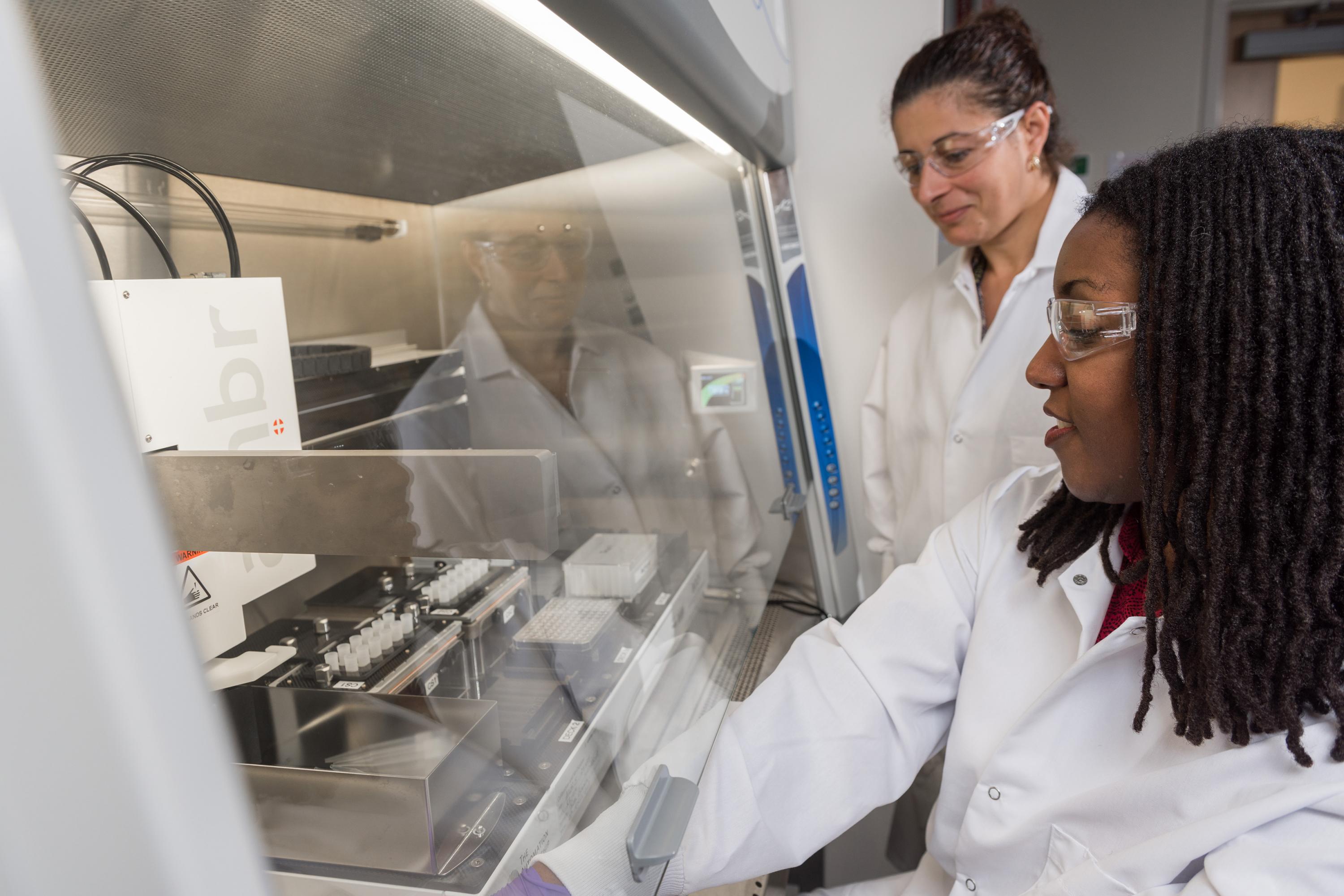

The goal of the training project is to develop course modules that can be used for certificate or graduate degree programs in biomanufacturing. The modules will be designed to give students instruction in traditional classrooms and through distance learning courses, covering topics such as cell processing and culturing, quality control and supply chain logistics. The modules will also train students in best manufacturing practices, regulatory compliance as well as cultural sensitivity and policy awareness.

The faculty team at Georgia Tech will focus on developing training that involves cell characterization and bioprocessing, logistics and supply chain management and other process-oriented aspects of manufacturing. Researchers at UGA will, among other things, focus on biopharmaceuticals process development, risk management and regulatory aspects, while the team at UPenn will develop training related to the delivery of cell and gene therapies as well as regulatory and entrepreneurial aspects of the industry.

“The upstream and downstream processing modules will have hands-on training components which will be benefit our students who rarely see biomanufacturing operations in a traditional university lab setting,” said David Blum, a co-principal investigator of this project and an associate research scientist and director of the Bioexpression and Fermentation Facility at UGA. Blum will work with colleagues in UGA’s College of Veterinary Medicine Educational Resources group and its Institute for International Biomedical Regulatory Sciences. “We are also excited about the use of virtual reality technology as part of our upstream process module, which will enhance the learning experience and result in more engaging content for students.”

The universities are also partnering with Merck, Akron Biotechnology LLC, RoosterBio and Unum Therapeutics, which will provide input on the curriculum during the development process.

“Recent FDA approvals of cellular therapies and the increase in investment by industry to manufacture these new medicines for patients has resulted in a great need for workforce development and education,” said Bruce Levine, a co-principal Investigator of this project and the Barbara and Edward Netter Professor in Cancer Gene Therapy at the University of Pennsylvania Perelman School of Medicine. “This NIIMBL project will allow us and our partners to build the foundation for training the cell manufacturing workforce.”

The overall NIIMBL effort involves more than 150 companies, academic institutions and other organizations and is being coordinated by the University of Delaware in partnership with the National Institute of Standards and Technology (NIST). The effort began two years ago with a private investment of at least $129 million from institute members across the country in addition to the federal funding.

The consortium aims to improve the way biological medicines, also known as biopharmaceuticals, are produced, with a goal of bringing down costs and finding ways to get the drugs into the hands of clinicians and patients faster.

The new curriculum development effort is just one of several cell manufacturing research projects ongoing at Georgia Tech. The Marcus Center for Therapeutic Cell Characterization and Manufacturing (MC3M) was established in 2016 and made possible by a $15.75 million gift from philanthropist Bernie Marcus, with a $7.25 million investment from Georgia Tech and another $1 million from the Georgia Research Alliance. In 2017, Georgia Tech was picked to lead the $20 million National Science Foundation Engineering Research Center for Cell Manufacturing Technologies (CMaT).

“Cell manufacturing has become a growing area of research at Georgia Tech, and we will leverage all of our resources and expertise in developing these course modules,” Zhang said.